The Third Industrial Revolution: changes in competency requirements. “anatomy of global technological revolutions” c.v.

The global industry today stands on the threshold of the fourth technological revolution, which is associated with the possibility of a radical modernization of production and the economy, as well as the emergence of such phenomena as digital production, the sharing economy, collective consumption, the “uberization” of the economy, the cloud model computing, distributed networks, network-centric control model, decentralization of control, etc. The technological basis for the transition to a new economic paradigm is the Internet of Things. This is stated in the J’son & Partners Consulting report on global trends and development potential of the Industrial Internet of Things in Russia.

In this regard, both new opportunities and threats are opening up for the domestic industry: in addition to the multiple lag in labor productivity and quality of products, a lag in the transition to new principles of interaction in the “supplier-consumer” chain may be added. This may lead to a fundamental impossibility of competing with leading international industrial concerns, both in terms of product costs and speed of order execution.

Internet of Things

Internet of Things (IoT, Internet of Things) is a system of unified computer networks and connected physical objects (things) with built-in sensors and software for collecting and exchanging data, with the ability to remotely monitor and control in an automated mode, without human intervention.

There is a consumer (mass) segment for the use of the Internet of Things, which includes personal connected devices - smart watches, various types of trackers, cars, smart home devices, etc. and the corporate (business) segment, which includes industry verticals and inter-industry markets - industry, transport, agriculture, energy (Smart Grid), smart city (Smart City), etc.

In this study, J’son & Partners Consulting consultants examined in detail the Internet of Things in the corporate (business) segment, which is called the Industrial Internet of Things, in particular, its application in industry - the Industrial Internet.

Industrial (often Industrial) Internet of Things (Industria lInternet of Things, IIoT) - Internet of things for corporate / industry use - a system of unified computer networks and connected industrial (production) objects with built-in sensors and software for collecting and exchanging data, with the possibility of remote control and control in an automated mode, without human intervention.

In industrial applications, the term “Industrial Internet” is used.

The introduction of network interaction between machines, equipment, buildings and information systems, the ability to monitor and analyze the environment, the production process and one’s own state in real time, the transfer of control and decision-making functions to intelligent systems lead to a change in the “paradigm” of technological development, also called the fourth industrial revolution.

The fourth industrial revolution (Industry 4.0) is the transition to fully automated digital production, controlled by intelligent systems in real time in constant interaction with the external environment, going beyond the boundaries of a single enterprise, with the prospect of unification into a global industrial network of things and services.

In a narrow sense, Industry 4.0 (Industrie 4.0) is the name of one of the ten projects of the German state Hi-Tech strategy until 2020, which describes the concept of smart manufacturing (Smart Manufacturing) based on the global industrial network of the Internet of Things and Services ).

In a broad sense, Industry 4.0 characterizes the current trend in the development of automation and data exchange, which includes cyber-physical systems, the Internet of things and cloud computing. It represents a new level of organization of production and management of the value chain throughout the entire life cycle of manufactured products.

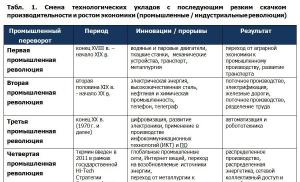

First Industrial Revolution (late XVIII - early XIX centuries) was due to the transition from an agricultural economy to industrial production due to the invention of steam energy, mechanical devices, and the development of metallurgy.

Second Industrial Revolution (second half of the 19th - beginning of the 20th centuries) - the invention of electrical energy, the subsequent mass production and division of labor.

Third Industrial Revolution (since 1970) - the use of electronic and information systems in production, which ensured intensive automation and robotization of production processes.

Fourth Industrial Revolution (the term was introduced in 2011, as part of the German initiative - Industry 4.0).

Despite the active introduction of various types of infocommunication technologies (ICT), electronics and industrial robotics into production processes, industrial automation, which began at the end of the 20th century, was predominantly local in nature, when each enterprise or divisions within one enterprise used its own (proprietary) management system ( or a combination thereof) that were incompatible with other systems.

The development of the Internet, ICT, sustainable communication channels, cloud technologies and digital platforms, as well as the information “explosion” that emerged from various data channels, ensured the emergence of open information systems and global industrial networks (extending the boundaries of an individual enterprise and interacting with each other), which have a transformative impact on all sectors of the modern economy and business beyond the ICT sector itself, and transfer industrial automation to a new, fourth stage of industrialization.

In 2011, the number of connected physical objects in the world exceeded the number of connected people. Since this time, it has been customary to estimate the rapid development of the Internet of Things era.

Despite the differences in the assessment methodology of various international analytical agencies, it can be stated that the application of the new concept will be associated primarily with the widespread use of the Internet of Things in economic sectors.

Foreign experts recognize the Internet of Things as a disruptive technology that brings irreversible transformation to the organization of modern production and business processes.

An analysis of the experience of implementing the Internet of Things in the world, carried out by consultants J`son & Partners Consulting, shows that the transition to the IIoT concept occurs due to the formation of cross-industrial open (horizontal and vertical) production and service ecosystems, combining many different management information systems of different enterprises and involving many different devices.

This approach allows you to implement in the virtual space arbitrarily complex end-to-end business processes that are capable of automatically implementing optimization management (end-to-end engineering) of various types of resources through the entire supply chain and creating the value of products - from idea development, design, engineering to production, operation and recycling.

To implement this approach, it is required that all necessary information about the actual state of resources (raw materials, electricity, machines and industrial equipment, vehicles, production, marketing, sales) both within one and at different enterprises be available to automated control systems different levels (drives and sensors, control, production management, sales and planning).

Thus, we can say that the Industrial Internet of Things is an organizational and technological transformation of production, based on the principles of the “digital economy”, which allows, at the management level, to combine real production, transport, human, engineering and other resources into almost unlimitedly scalable software-controlled virtual ones resource pools (shared economy) and provide the user not with the devices themselves, but with the results of their use (device functions) through the implementation of end-to-end production and business processes (end-to-end engineering).

“Until now, companies could only manage part of the production process, never being able to see the whole picture. And optimizing each individual part of this process optimizes the entire chain. We also had difficulty maintaining supply stability, productivity and efficiency. If you look at transportation, 75% of the total volume was provided by trucks, which created problems.

Today, with ABB, we can offer businesses the ability to connect all production facilities almost in real time. To see what is happening to it, have feedback with them, control them, identify and avoid various problems and pitfalls with different stages of production, individual services and simplify equipment inventory. This gives a whole new level of optimization. Hence - productivity growth, innovation, any aspect important for the enterprise. But this is only one direction. Think automation, robots, 3D printing..."

From the speech of a Microsoft representative at the IoT World 2016 conference, USA (Çağlayan Arkan – General Manager, Worldwide Manufacturing & Resources Sector, Enterprise & Partner Group)

The introduction of the Internet of Things requires a fundamental change in approaches to the creation and use of automated information management systems (ACS) and general approaches to the management of enterprises and organizations.

“From a technical point of view, the Internet of Things is very easy to implement. The most difficult part is changing business processes. And I have never seen a single company come to you one glorious day and offer you such a magical solution.”

From a speech by a Baker Hughes representative at the IoT World 2016 conference, USA (Blake Burnette - Director, Equipment Research and Development)

According to J’son & Partners Consulting, behind the quantitative growth of the Internet of Things and the organizational and technological transformation of production are important qualitative changes in the economy:

- data that was previously unavailable, with the increasing penetration of embedded devices, represents valuable information about the nature of product and equipment use for all participants in the production cycle, is the basis for the formation of new business models and provides additional income from the offer of new services, such as, for example: contract life cycle for industrial equipment, contract manufacturing as a service, transport as a service, security as a service and others;

- virtualization of production functions is accompanied by the formation of a “shared economy”, characterized by significantly higher efficiency and productivity by increasing the use of available resources, changing the functionality of devices without making changes to physical objects, by changing their management technologies;

- modeling of technological processes, end-to-end design and, as a result, optimization of the value chain at all stages of the product life cycle in real time, make it possible to produce a piece or small-scale product at a minimum price for the Customer and with a profit for the manufacturer, which in traditional production is only possible with mass production;

- Reference architecture, standardized networks, and a rental model rather than paying full cost of ownership make shared manufacturing infrastructure available to SMBs, facilitating their production management efforts, enabling faster response to changing market demands and shorter product life cycles, and entails development and emergence of new applications and services;

- analysis of data about the user, his production facilities (machines, buildings, equipment) and consumption patterns opens up opportunities for the service provider to improve customer experience, create greater ease of use, better solutions and reduce customer costs, which leads to increased satisfaction and loyalty from working with by this supplier;

- The functioning of various sectors of the economy will continuously become more complex under the influence of technological developments and will increasingly be carried out through automatic decision-making by the machines themselves based on the analysis of large amounts of data from connected devices, which will lead to a gradual reduction in the role of production personnel, including qualified ones. High-quality professional education, including engineering, special educational programs for workers and trainings will be required.

A striking example of the application of the Internet of Things concept in industry is the company’s project Harley Davidson, which produces motorcycles. The main problem the company faced was the slow response to consumer demands in an increasingly competitive environment and the limited ability to customize the five models produced by dealers. From 2009 to 2011, the company carried out a large-scale reconstruction of its industrial sites, as a result of which a single assembly site was created that produces any type of motorcycle with the possibility of customization from more than 1,300 options.

Sensors controlled by an MES (SAP Connected Manufacturing) class system are used throughout the entire production process. Each machine, each part has a radio tag that uniquely identifies the product and its production cycle. Data from sensors is transferred to the SAP HANA Cloud for IoT platform, which serves as an integration bus for collecting data from sensors and various information systems, both internal production and business systems of Harley Davidson, and information systems of the company’s counterparties.

Harley Davidson has achieved fantastic results:

- Reducing the production cycle from 21 days to 6 hours (every 89 seconds a motorcycle comes off the assembly line, completely customized for its future owner).

- The company's shareholder value has increased more than sevenfold from $10 in 2009 to $70 in 2015.

In addition, end-to-end management of the production of a product (motorcycle) has been implemented throughout its entire life cycle.

Another example of the implementation of the Industrial Internet is the Italian company Brexton is a manufacturer of stone processing machines that deployed an intelligent system based on the Microsoft ecosystem, as a result of which it became possible to connect the machines to remote servers of the control center, which stores production data and inventory information. The stone cutting and processing machines themselves are controlled by programmable logic controllers (PLC) connected to an HMI (Human Machine Interface). The HMI is connected to the Breton PLC using ASEM Ubiquity. The operator can access the network using the HMI, select the required specification, and use the barcode scanner to scan the data. All data required for the production of a specific sample is automatically downloaded to the PLC. The process does not require the use of paper instructions, manual adjustments, or manually running a stone cutting machine.

The solution allows you not only to manage and configure the operation of machines, but also to provide technical support in the form of a chat in real time. Breton plans to significantly reduce travel costs for its experts through remote service: 85% of the company's clients are located outside Italy. The company estimates the savings at 400 thousand euros.

Clients also benefit. Thus, the Taiwanese company Lido Stone Works, a manufacturer of custom-made stone products, installed three Breton machines and switched to automated production. The solution linked the design department with the production workshop, as a result of the implementation of the new system, Lido Stone Works received the following indicators:

- revenue growth by 70%;

- productivity increase by 30%.

Constraining factors and requirements for the implementation of IoT projects in Russia

Ecosystem and partners. To implement projects in the field of Internet of Things, it is necessary to form an entire ecosystem, including:

- availability in Russia of an IoT platform for collecting, storing and processing data, both global and national;

- the presence of an extensive pool of application developers for IoT platforms;

- a sufficient number and range of devices capable of interacting with platforms, so-called connected devices;

- the presence of enterprises and businesses in general, the organizational model of which allows for transformation, and so on.

If IoT platforms are already available in Russia, then the main difficulties are still associated with the development of application services and, most importantly, the organizational readiness of potential customers. At the same time, the absence of at least one of these components makes the transition to Internet of Things technologies impossible.

Governmental support. The implementation of Internet of Things projects in the world is actively supported by the state in the form of:

- direct government funding;

- public-private financing together with the largest players;

- working and project groups are formed from representatives of the industry and research institutions;

- test zones are organized and infrastructure for sharing is provided;

- competitions and hackathons for creating applications and developments are organized;

- pilot projects are supported;

- research and development are funded in various areas of implementation (artificial intelligence, management information systems, security, networking, etc.);

- export of developments is supported;

- Most large countries have approved long-term government programs to support the Internet of Things.

For example, the Industrie 4.0 project is recognized as an important measure in strengthening German technological leadership in mechanical engineering, and direct government funding of $200 million is expected for its development.

Additionally, for the implementation of the program, funding is provided for innovative research in the field of ICT through the Ministry of Education for the study of:

- intelligence of embedded devices;

- simulation models of network applications;

- human-machine interaction, language and media management, robotics services.

The technological systems and equipment of industrialized countries are becoming intelligent and connected. Enterprises are integrating into global industrial networks to connect a network of manufacturing resources and global applications.

This model is also called shared economy. It is based on the postulate that in any isolated system, the “exclusive” use of resources/devices is ineffective, regardless of how technologically “advanced” these devices/resources are. And the smaller such an isolated system, the less efficiently its resources are used, regardless of how technologically advanced they are.

Therefore, the task of IoT is not simply to connect various devices (machines and industrial equipment, vehicles, engineering systems) to a communication network, but to combine devices into software-controlled pools and provide the user not with the devices themselves, but with the results of their use (device functions).

This allows you to multiply the productivity and efficiency of using pooled devices relative to the traditional model of informationally isolated use and implement fundamentally new business models, such as, for example, a life cycle contract for industrial equipment, contract manufacturing as a service, transport as a service, security as service and others.

This possibility is achieved through the implementation of the cloud computing model in relation to physical objects (devices, resources equipped with built-in intelligent systems). Unlike proprietary (closed) automation systems, an unlimited number and range of devices and any other data sources can be connected to the IoT platform using open APIs, and the “big data” effect allows you to improve data analysis algorithms using machine learning technologies.

That is, the Internet of Things is not special high-tech devices, but a different model for using existing devices (resources), a transition from selling devices to selling their functions. In the IoT model, using a limited range of already installed devices, it is possible to implement almost unlimited functionality of devices without the need to make changes (or with a minimum of them) to the devices themselves, and thus achieve maximum utilization of these devices. In principle, achieving 100 percent efficiency in such systems is limited only by the imperfection of automatic resource management algorithms. By comparison, device recycling in traditional isolated systems is typically 4-6%.

Thus, we can say that the implementation of the Internet of things does not require significant changes in the connected devices themselves, and, as a result, capital costs for their modernization, but it does imply the need for a fundamental change in approaches to their use, consisting in the transformation of methods and means of collection and storage and processing data on the state of devices and the role of humans in data collection processes and device management. That is, the implementation of the Internet of Things requires a change in approaches to the creation and use of automated information management systems (ACS) and general approaches to the management of enterprises and organizations.

The main challenge in the medium term for Russia is the threat of loss of competitiveness on the world stage due to the lag in the transition to the sharing economy, the technological basis of which is the Internet of Things model, which will be reflected in an increase in the gap in labor productivity from the United States from fourfold in 2015 to more than tenfold in 2023.

And in the long term, if adequate measures are not taken, the emergence of an almost insurmountable technological barrier is predicted between Russia and the leading technological powers that rely on the introduction of highly efficient technologies and service deployment models, the operation of information and communication infrastructure and software applications, such as virtualization of network functions and automatic software control of them. This could lead to a reduction in the volume of ICT consumption in Russia in monetary terms by more than half in 2023 compared to 2015 and technological degradation of the ICT infrastructure deployed in the country, as well as to the isolation of Russian ICT developers from participating in actively developing current global development ecosystems and test environments.

In an optimistic scenario, the emergence and accelerated implementation of fundamentally new business and service models in the IoT ideology, taking into account government support and accompanied by R&D, as well as the possibility of creating an open competitive economy using technical means based on a fundamental change in the role of ICT in the management of manufacturing enterprises, will be key point of growth of industry and the Russian economy for the next three and subsequent years.

If we consider that in terms of labor productivity, that is, in terms of the integral indicator of resource efficiency, Russia lags 4-5 times behind the USA and Germany, then the growth potential for our country is many times higher than that of the so-called developed countries. And this potential must be used through joint, well-coordinated efforts of the state, business, players, scientific and research organizations.

Obviously, the economic crisis will push Russian business to implement efficiency improvement projects. If we take into account that the transition to using the IoT model makes it possible to increase it by several times, and not by a fraction of a percent, and with virtually no capital investments in the modernization of fixed assets, then the consultants of J'son & Partners Consulting expect to see more than just “stories” this year success" of new IoT projects in Russia.

About 150 years ago - primarily in economic research - the fact of the existence of small, medium and large development cycles was recorded. Among the first to note the phenomenon of undulating economic development was the little-known English railway engineer Hyde Clark, who studied price dynamics, time intervals of famine, low and high yields and was confident that he had recorded the cyclical nature of data changes. G. Clark believed that 54 years pass from crisis to crisis.

Subsequently, Clement Juglar in 1862, studying the crises in Britain, France and the USA, noted fluctuations in the levels of inventories of goods, production utilization, volumes of investment in fixed assets and calculated that the average time between crises was 7-10 years. Also, Joseph Kitchin, using material from Great Britain and the USA, recorded small cycles lasting 40 months (later named after him) and, following C. Juglar, medium cycles lasting 7-11 years.

M.I. Tugan-Baranovsky tried to give a theoretical explanation of the reasons for cyclicality and in 1894 wrote that “economic prosperity mainly comes through expansion in international markets,<которое>associated with increased free trade and improved transport systems. Following him, Jacob van Gelderen and Salomon de Wolf in the 1910s suggested that technological progress was the reason for the undulation of economic development. This idea was almost simultaneously productively developed by the Russian scientist Konstantin Kondratiev, using a large amount of empirical material to show that a change in the package of technologies causes a cycle of economic development of 48-60 years.

A little later, Simon Kuznets in 1930 discovered waves lasting 15-25 years, from his point of view, associated with the influx of immigrants and periodic mass renovation of housing by a new generation, and Joseph Schumpeter productively developed the concept of large Kondratieff cycles.

In accordance with the economic concepts mentioned above, development processes are uneven and unstable: any process can be described on the basis of cyclical models; it has its beginning, a rise phase, a peak and a decline phase. The transition from one cycle to another usually occurs through a change in technology, lifestyle, social structures and can be described in terms of a structural crisis.

In recent years, the metaphor of the “third industrial revolution” has been revived in popular literature—particularly in the work of Jeremy Rifkin. According to this concept, each industrial revolution is characterized by its own type of basic energy carrier, its method of converting energy into mechanical energy, its own type of transport and type of communication. The unity of these key moments of the industrial production structure forms the basis of a long economic cycle, and their change changes the type of economy and the method of industrial development

From this point of view, the “Zero Industrial Revolution” in the Netherlands was peat, wind turbines, canals and trequarts (canals along which ships or barges were pulled by horses walking along the roads along the canal; therefore, movement along trequarts did not depend on the presence and direction of the wind, and barges between cities ran on a schedule every hour from the opening to the closing of the city gates). Not only peat, cargo and people, but also mail were transported along canals and trequarts; therefore they also acted as a means of communication. The massive use of wind turbines acted not only as a source of local energy, but also made it possible to drain large areas of land, reclaiming them from swamps and the sea, creating the so-called “polders” - new lands for agricultural and industrial use.

The first industrial revolution brought coal, the steam engine, the railroad, and the telegraph. The leader in it was England, which created a new infrastructure package based on these technologies and took the lead from the Netherlands. England transferred and, due to the development of science and design (dictating completely new requirements for human qualifications), as well as protectionist policies, improved the experience of the Netherlands in shipbuilding, intensive agriculture, and weaving, on which the base rate was subsequently made. As a result, about half of weaving products in 1800 were exported to the world market, and the products of English enterprises accounted for more than 60% of the world market. On the basis of the new infrastructure package, the mining industry and the production of coke, high-quality and, most importantly, cheap cast iron and malleable iron, and precision engineering were developed.

The Second Industrial Revolution relies on oil, the internal combustion engine, the automobile and airplane, electricity, and related communications (telephone and radio). The lead in this industrial revolution belonged to the United States. Many countries began to create elements of a new infrastructure package almost simultaneously with the United States: Russia also produced oil and exported its products; The internal combustion engine, the automobile, and then quality roads were created in Germany; a unified energy system was implemented in Japan and Korea. But the United States was the first to fully deploy the new infrastructure package, and this gave it an advantage in development. The country has significantly replaced the previous leader, Great Britain, in weaving and exporting fabrics. In the 1920s, the Ford Corporation alone (and there were others) owned three-quarters of the world's automobile market, spanning thirty-six countries on three continents. To implement these steps, the United States needed to transform research and design, which had previously been carried out by outstanding individuals, into professions, and their organization into research and design companies that conduct research and development in many areas and, in cooperation between these areas, create elements of a new technological package (it is clear that in these conditions one of the key competencies was the ability to participate in research and design cooperation and organize it).

The third industrial revolution, from Rifkin's point of view, is the Internet as a means of communication. Let’s add – and the joint work of participants and teams distributed around the globe. And the “energy platform” of the third industrial revolution has not yet taken shape. D. Rifkin believes that this role can be played by small renewable energy sources in homes, offices and enterprises, Smart Greed, which will connect these “consumers-generators” and solve the problem of unsynchronized generation and consumption, hydrogen fuel cells as renewable energy batteries, and also vehicles with a hydrogen fuel cell battery.

D. Rifkin argues that the cause of today's crisis is high energy prices, in particular oil. In the second half of the 20th century. China, India, Brazil, Mexico and a number of other Third World countries joined the industrialization processes. However, ways to industrialize without increasing or even maintaining energy consumption have not yet been invented. Because of this, energy consumption has increased - in 1978 the maximum level of oil consumption per capita of the Earth's population was reached, and since then the increase in oil production has been slower than the increase in population. When energy shortages led to an increase in the cost of a barrel of oil to $120-150, a significant part of consumers were not ready to pay for more expensive products, and economic growth slowed down. The financial crisis was only a consequence of the suspension of economic growth and consumer pessimism. After 2008, there were several situations when the world economy began to “accelerate”, energy consumption increased, but economic growth was again “limited” by rising prices – in particular oil. Therefore, until a transition to new energy sources is made, which will provide producers with cheaper energy, there will be no way out of the economic crisis, according to Rifkin.

From our point of view, rising energy prices are only one of the visible components of the crisis. As the experience of the first three industrial revolutions (including the so-called “zero”) shows, any crisis indicates a lack of the existing infrastructure package. Stagnation and crisis occur when old infrastructures become insufficient and cease to provide resources to new and old processes. The crisis continues until new infrastructures are formed. New technologies and the elements of the new infrastructure package based on them begin to take shape at the end of the old cycle, but until a full-fledged new technological and infrastructure platform is formed from them, which will provide resources for new processes, there will be no way out of the crisis.

Rifkin’s works, from this point of view, in a rougher and simpler form continue the research of the cyclists - including the above-mentioned Russian scientist of the early twentieth century. N.D. Kondratieva. Kondratiev based the so-called “large cycles of conjuncture” on a change in basic technologies and argued that before and at the beginning of the “increasing wave” of a large cycle, major discoveries and inventions occur, generating significant changes in production, trade and the place of the countries that carried them out in the global division of labor; The upward wave of the large cycle is also saturated with social changes.

Today we are inclined to assume that, in addition to the technological processes that Kondratiev paid attention to, large development cycles are also based on processes of social dynamics and generational change. The indicated time parameters of the cycles, 47-60 years, empirically “discovered” by Kondratiev, are most likely due to the fact that this is a cycle of life and the change of three generations, each of which, as modern research shows, takes 16-21 years (while in In the twentieth century, these periods are increasing rather than decreasing). Actually, this is, from our point of view, the chronotope of the “Kondratieff” cycle. It is the change of three generations that sets the “unit” of cyclicity.

Looking at the three industrial revolutions through the prism of these ideas, we see that here too we can see the role of technological and social factors. From a technological point of view, in order to start a new industrial revolution, it is necessary that an “infrastructure package” be formed, on the basis of which the problems of the past cycle will be overcome.

Therefore, the first wave is associated with the accumulation of disparate innovative solutions, which later become elements of a new package. This is the innovation phase. At the next stage, the new package has already taken shape - usually this happens in the leading country or region and can be borrowed by countries that are catching up with industrialization as a whole. However, here we are faced with scaling difficulties, the reasons for which lie in the sphere of culture and consciousness. The most conservative moment in development is people with their usual mental models, ways of thinking and doing. The challenges of scaling a new technological structure can only be solved by restructuring the education systems and mass training.

If we now return to the metaphor of the Third Industrial Revolution, then today we are in a situation very similar to the beginning of the 18th century, when the main “puzel1s” of the first industrial revolution took shape, or at the end of the 19th century, when a new infrastructure package of the modern economic system was being formed . The crisis of the beginning of the 21st century is associated with the exhaustion of the resource capabilities of the second industrial revolution and the infrastructures supporting it. And today we are at its initial stage, when key innovative solutions are being developed.

We don’t yet know what they will be: the search is going on simultaneously in different directions. Moreover, successful decisions in one area or another (for example, in energy) will depend on decisions in other areas - until a sustainable infrastructure package is put together. The country or region that does this for the first time on its territory will objectively take the place of the leader of the world process. It can be assumed that the new assembly will be completed by 2020-2030. But as soon as it arises, a massive replacement of old economic and social structures with new ones will begin. The process will enter its active phase; this will lead to a gigantic release of people from old industries and the disappearance of a number of professions. We will witness the loss of jobs by a mass of industrial workers - including in developed countries - due to further automation and robotization of industrial production against the backdrop of pressure from unclaimed labor resources from the newly industrialized countries of the Asia-Pacific region, Africa and Latin America. Serious changes will also affect social and political institutions, social mobility, healthcare and education.

So, we are at the peak of the innovative phase of a large development cycle. The leading technological structure is changing. The basic technologies and infrastructure foundations of the Third Industrial Revolution are being formed.

It’s good to describe history: we see traces of a process that has already taken place. It is difficult to predict: there are several different options for pre-construction of the technological platform of the Third Industrial Revolution. But the main thing is: in a situation of transition from one development cycle to another, from one platform to another, old meanings are blurred and cease to determine human behavior and action. What was in demand 10 and even more so 20 years ago is no longer needed. People who received good training in the old technological order are left without work and livelihood. The boundaries of professional communities and types of activities are blurring. A person trained according to old patterns is more likely to be a brake on innovation than its creator. Having taken out a loan and paid crazy amounts of money for higher education, a young man cannot find a job in his specialty and ends up “bankrupt” without having done or undertaken anything yet.

There is no need to think that no one sees or knows this. A young man is already in high school, and sometimes even earlier, hears about this from adults and through the media, reads on the Internet and discusses with peers. Under these conditions, obtaining a traditional education is questionable. It is meaningless in the new situation.

The article very briefly examines the four technological revolutions that have already taken place, which led to the replacement of objects of competition (knowledge, technology and the production of machines and mechanisms). The actions of motive power (water, steam, electricity and hydrocarbons) were directed to these objects. Then, starting from the fifth technological structure, a revolution occurred, which marked the transition to a qualitatively new design, directing the actions of its intellectual forces to new objects of competition, namely to different types of convergence of nano, bio, info and cogno technologies. At the same time, actions aimed at a new subject of competition began to use a new logic of cooperation (division of labor, use of the best standards and exchange of experience), which provided access to the intellectual powers of the global cloud technological resource.

Introduction

Humanity has experienced five technological revolutions. Every time the transition from one technological structure to another is accompanied by a crisis and destruction of the old technological structure of the economy. This is due to the fact that the need for old technologies and products produced with their help decreases over time, and the need for resources increases. As a result, enterprises incur unexpected expenses, lose their customers, profits, and banks become more cautious in issuing loans, investors tend to go to the bottom (stock market) in the hope of preserving their capital. All this taken together promises numerous problems for entrepreneurs who, for one reason or another, did not have time or do not want to direct their actions to a new subject of competition (knowledge, technology and production of products with new values), which inspires confidence among investors and consumers of products.

In each technological structure, competing items from several previous structures can be used. For example, in Russia, technologies of the third (electric drives of various machines and mechanisms developed at the beginning of the last century), fourth (current oil and gas production platforms) and fifth technological structures (cloud communications of enterprises using computers) are currently used as a subject of competition. electronic governments, INTERNET). But gradually, in the depths of the next technological order, technologies of the subsequent technological order are maturing, the actions of which are aimed at modernizing the objects of competition from previous technological orders.

For example, hydrocarbon production technologies rightly belong to the subjects of competition from the fourth technological order. Various internal combustion engines require these items. But technologies of the fifth technological order are capable, with the help of special additives produced using nanotechnology, to significantly increase the wear resistance of resource extraction tools. Such modification of competitive items produced in the era of the fourth technological order allows one to significantly extend their life cycle and maintain their competitive advantages at the proper level.

In Fig. Figure 1 shows the main system design that characterizes competition in each technological structure. The subject of competition includes knowledge, technology and production. Actions aimed at objects of competition include various methods of converting resources into motive or intellectual power, as well as various logics of action (division of labor of technological chains, exchange of world experience and use of the best world standards).

When moving to the next technological structure, the entire system structure, containing objects and actions aimed at competition, inevitably changes. The old design no longer satisfies entrepreneurs, since the costs of its maintenance are constantly growing in geometric progression, while labor productivity is growing in arithmetic progression. Changing the design increases the investment attractiveness of enterprises and allows one to significantly reduce the costs of actions aimed at new areas of competition.

1. The first technological revolution

In different countries, the emergence of the first technological structure and related objects and actions of competition took place in 1785–1843, but this emergence occurred first in England. At that time, England was the largest importer of cotton products. This meant that the objects and actions of British industrialists did not meet the requirements of global competition. This situation could only be reversed with the help of a design that replaced human labor with universal motive force. Using the concepts of objects and actions of competition in Fig. 1, it can be argued that English industrialists, finding themselves unable to compete with Indian weavers, whose fabrics were better and cheaper, tried to study competition items, that is, to accumulate knowledge, master new technologies and mechanize fabric production using transformation of resources into motive power, as well as a new logic of action based on manufactories(actions aimed at dividing labor in the production of yarn and fabrics).

With the invention of spinning and weaving looms, the technological revolution of the cotton industry was not yet over. The fact is that a textile machine (like any other machine) consists of two parts: a working machine (tool machine), which directly processes the material, and an engine (resource), which drives this working machine. The technological revolution began with the machine-tool. If before this a worker could work with only one spindle, then the machine could rotate many spindles, as a result of which labor productivity increased by about 40 times. But there was a discrepancy between the machine's performance and its motive power. To eliminate this discrepancy, it was necessary that the driving force of textile machines be the force of falling water.

But all this industrial development was jeopardized due to lack of necessary resources. There were not fast-flowing rivers everywhere, so there was a real war for water between entrepreneurs. Owners of land along the river banks did not miss the opportunity to get their share of the profits by increasing the price of plots of land. In essence, land owners played the role of unscrupulous distributors. Therefore, it was desirable for the entrepreneur to get rid of the need to pay significant amounts of money in the form of rent to the landowner, whose monopoly was the land on the river bank. All this taken together forced entrepreneurs to actively search for a new driving force capable of providing growing labor productivity with sufficient resources. And such motive power was found in the form of steam. As a result, the shortage of the “water” resource led to a change in design, that is, to the objects and actions of the “steam resource”. Competition and cooperation of small textile enterprises gave way to competition and cooperation of technological chains of large manufactories.

2. Second technological revolution

This revolution began in 1780–1896 with the invention of a universal steam engine by James Watt, which could be used as an engine for any working mechanism. Back in 1786, the first steam mill was built in London; the year before, the first textile steam factory was built. This completed the process of mastering a new subject of competition, shown in Fig. 1, consisting of knowledge, technology and production of various steam engines and mechanisms. Actions, aimed at this subject of competition were based on use of steam propulsion, as well as on logic of action, based on the division of labor and the use of new quality standards for textile production.

With the advent of steam, factories could leave river valleys, where they were located in seclusion, and move closer to markets, where they could have raw materials, goods and labor. The first steam engines, which appeared in the 17th century, played a significant role in other types of economic activity. Thus, James Watt's steam engine could be used as a universal platform in various industries and transport (steam locomotives, steamships, steam drives of spinning and weaving machines, steam mills, steam hammers), as well as other operations. At the same time, the history of the invention of the universal steam engine once again proves the validity of the Chinese formula of “investment happiness” in that a technological revolution is not just a chain of inventions. The Russian mechanic Polzunov invented his steam engine before Watt, but in Russia at that time it was not needed and was forgotten, as they apparently forgot about many other “untimely” inventions.

3. Third technological revolution

The third technological revolution took place in 1889–1947 as a result of attempts by entrepreneurs to maintain their competitiveness at the proper level. But the previous subject of competition, shown in Fig. 1 (knowledge and technology for the production of steam engines), and actions with it no longer meet the new requirements for price and quality of products. Numerous steam engines required constant maintenance and human presence. This did not suit steam consumers, and the world began to search for another system design that would significantly increase the service life of the motive power. Subject to global competition steel electrical machines and mechanisms built into new means of production, and actions, aimed at them, began to use the motive power of electricity. Again it was necessary to accumulate knowledge and technology for producing new motive force and invent a new design for accessing this motive force. The key moment in the onset of a new technological order was the invention of Thomas Edison and his subsequent actions to create private companies using the electrical resource. The invention of the possibility of transmitting electricity made it possible to use new forms of division of labor, new technologies based on electric drives and simple conveyors.

It should be noted that the essential side of Thomas Edison’s activity was not the talent of an inventor, but the genius of an entrepreneur and technologist who brought inventions to life. In addition to the light bulb, everyone knows that Edison developed an alternating current generator and made significant contributions to the design of the phonograph, movie camera, telephone, and typewriter (he did not invent all of this). In the era of the third technological order, the technology for converting resources into electrical energy, as well as generating, transmitting and using electrical energy, has been improved. The power of stations and the length of networks grew, individual energy complexes were connected by high-voltage transmission lines, and there was a gradual transition from centralized power supply to individual enterprises to the electrification of entire countries. The proliferation of electrically powered objects and activities in manufacturing contributed to the efficient division of labor in industry. The main achievement of the third technological structure was that only electrical energy was able to finally bridge the gap between the location of natural energy resources (water sources, fuel deposits) and the location of its consumers. They learned to obtain the motive “electric” force of magnetoelectric machines back in the 30s of the 19th century, but in practice this type of current was recognized and appreciated only in the next technological structure.

4. The fourth technological revolution

The fourth technological structure (1940-1990) arose in the depths of the previous “electric” structure and began to be used as main subject of competition in Fig. 1 knowledge and technologies aimed at converting hydrocarbon energy into universal motor force. As a result of actions aimed at this subject, internal combustion engines appeared and cars, tractors and airplanes and other machines and mechanisms were built on this platform. Nuclear energy began its development long before its use in the economies of countries. This proves that in life there is a constant process of updating knowledge, technology and the production of resources and the ensuing design of converting resources into different types of motive power. This process is not fast due to the human factor, which is inherent in the socio-economic system. However, the strategic vision of the most advanced entrepreneurs and their desire to ensure long-term global competition gradually led to the formation of new forms of cooperation.

The fourth technological structure significantly changed the appearance of the technological structure of the economy (tractors, mechanisms based on internal combustion engines, etc.) and actually ended the age of mechanization in various types of economic activity. The most important event was the invention of new activities aimed at competitive objects (cars), namely the assembly line for the production of cars, as well as tractors, airplanes, and so on. Mechanized household appliances, small-sized mechanisms for processing food, and later electric shavers, vacuum cleaners, washing and dishwashers, musical devices and complexes, etc. appeared in everyday life of citizens.

For this technological order, oil and gas, as well as their derivatives, became the most important global technological resource. Gradually, this resource was transformed into different types of motor force. Through these driving forces, many developed countries have provided themselves with the necessary economic growth. With the help of new types of propulsion forces, the economy of arms competition has flourished, based on the use of internal combustion engines of various types. On this basis, various platforms emerged for the production of new models of machine tools, aircraft, tanks, cars, tractors, submarines and ships, and other military equipment. These platforms, provided with the propulsion power of internal combustion engines, have themselves become a global subject of competition, to which production networks of enterprises have begun to act.

Thus, the fourth technological structure increased the competitiveness of the economy due to new competition items(knowledge, technology and production of systems on the internal combustion engine platform). These items were targeted actions of technological chains enterprises on the division of labor, on the application of new quality standards and on the exchange of experience with other entrepreneurs.

It should be noted that for the only time in the history of the development of the Russian Empire, the USSR was able to quickly master the competition of the fourth technological order in the period 1930-1940 and, in particular, in the field of weapons. This happened thanks to the country’s enormous resources, as well as competent actions of the authorities aimed at creating technological chains of enterprises, division of labor, timely training of competent personnel, use of the best standards and taking into account the experience of the United States and Germany in the production of weapons.

5. Fifth technological revolution.

The trigger for the fifth technological revolution was the invention of the transistor in 1956 by American physicists William Shockley, John Badin and Walter Bratten. For this invention, the authors were jointly awarded the Nobel Prize in Physics. The transistor revolutionized radio technology. It gave rise to new competition subjects in Fig. 1, based on the achievements of microelectronics and, ultimately, led to the creation of microcircuits, microprocessors, computers and many other communication systems without which we currently cannot imagine our lives. This was a way out of the “primitive mechanical” age into the electronic, space and computer age.

At this stage, for the first time in history, the subject of competition in Fig. 1 (knowledge, technology and production) ceased to serve the purpose of simply replacing human labor with the motive power of machines, as in previous structures. Instead of this subject of competition began to serve the goals of developing hitherto unknown intellectual forces of mass automation of production, product design and enterprise management. As a result, at the turn of the century the most complex interdisciplinary intellectual forces automation of product design (CAD), technology management (ACS) and enterprise management (ACS). Actions, These forces have led to a new logic of division of labor, exchange of world experience and application of the best world standards using cloud Internet technologies. Such actions began to be completely another way to transform resources into intellectual power, which received the name cloudy from the words “ cloud computing (cloud computing)".

It should be noted that during the fourth technological order, the resource of intellectual power already existed, but it was relatively small, and there were few consumers. In the initial stages of the development of cloud computing, the resource was used by employees of universities and research laboratories for collective creativity to create intellectual power sufficient to create inventions and discoveries. Subject to competition was the creation of various catalogs of knowledge, technologies for the production of components. This subject was addressed actions to transform available resources into intellectual power catalog knowledge.

The pioneer in the field of converting available resources into the intellectual power of knowledge was the Yahoo search engine. It was not a knowledge platform in the truest sense because the scope of knowledge search was limited to catalog resources. Then catalogs spread and began to be used everywhere, and search methods developed along with them. At the moment, catalogs have almost lost popularity. This is because the modern knowledge platform contains a huge amount of intellectual power derived from resources through associative modes of action.

Today's competition includes the Open Directory Project, or DMOZ, knowledge directory, which contains information on 5 million resources, and the Google search engine, which contains about 8 billion documents. Actions aimed at these competitive items have allowed search engines such as MSN Search, Yahoo and Google to reach an international level of competition. In this area, new subjects of competition (platforms of knowledge, technologies) have yet to be identified, which will be targeted by the convergence of technologies, which are still poorly studied and inaccessible to the mass user. It follows that the fifth technological revolution is still ongoing and many new inventions and discoveries await us.

6. The sixth technological revolution

This revolution is still ahead and, unlike the previous ones, for the first time in the history of mankind, it considers as actions aimed at the main subjects of global competition in Fig. 1 (knowledge, nano, bio, information and cognitive technologies), not motive power, but primarily intellectual forces person. Actions taken in the previous technological order in the field of cloud communications and information retrieval systems led to the fact that investments in the form of global cloud technology resource, shown in Fig. 2. During the fourth and fifth technological orders, global competition throughout the world was supported by a powerful global resource (dollars), emanating mainly from the United States and lending to numerous, mainly American buyers.

The main driving force of enterprises aimed at competition has become consumer credit. At the same time, lenders turned a blind eye to the fact that credit risks were increasing and a significant part of borrowers did not repay their loans. But on the other hand, the huge demand for goods and services in the US market was maintained, which served as a driving force for improving the life cycle parameters of manufacturers of products of the fifth technological order in the US, EU countries, China and other countries. During the transition of the world economy to the sixth technological structure, a systemic failure occurred, which was expressed in the depletion of credit resources. This failure led to the collapse of the global financial system and investment market. Now, from the ruins of the old model, the outlines of a new model are emerging, focused on means of improving investment attractiveness and other parameters of the life cycle of manufacturers through systemic innovative breakthroughs. In other words, credit as the driving force of the economy has given way to intellectual force aimed at the convergence of high technologies.

Nowadays, a new technological structure is emerging from the massive application of innovations in various types of economic activity. Its main subject to global competition raises knowledge, technology and production of intellectual power to unprecedented heights of collective creativity. Actions aimed at the main subject of competition identify and eliminate discrepancies between the requirements of investors and the growing complexity of actions aimed at different ways of converting resources into intellectual power and at different logics of the division of labor.

It became clear that the system design, consisting of technology parks, clusters, and venture funds scattered around the world, in the new conditions is clearly not capable of implementing such projects. At the same time, the role of enterprise cooperation, the use of the best world standards and the exchange of knowledge and competencies has grown incredibly.

To transform investment resources into new forms of intellectual power, a new so-called global cloud technology resource of knowledge, technologies and products that reduces investor risks and ensuring the implementation of systems with a high level of artificial intelligence. And to access a new global cloud technological resource, you need a completely different system design, which should provide access for innovative businesses from around the world to a new resource with the purpose of producing new types of intellectual forces. This design is represented in Fig. 2 by a certain set of intelligent shells connected to each other across the globe using cloud communications. Each intelligent shell in turn consists of a set of functional platforms.

Each platform supports specific norms, rules and resulting standards for transforming resources into new types of intelligence, is filled with a variety of complex design decisions in different countries, and is capable of quickly identifying and eliminating inconsistencies between them. Thanks to this, the shell with platforms is integrated into a new global cloud technological resource, which can be transformed into a resource of intellectual power available to other producers, distributors and consumers of knowledge, developers and suppliers of technology, producers of intellectual power from around the world. Moreover, the shell itself and its logic of action (Fig. 1) serve as the basis for cooperation between enterprises, providing for the international division of labor, the application of the best world standards and the exchange of world experience.

The number of platforms in each intellectual shell serves as the main feature of a certain type of enterprise activity. If we are dealing with shells consisting of two platforms (technology transfers and product production), then this circumstance clearly indicates that we are able to successfully modernize the economy through the import of technologies and production of products. If we use shells consisting of three platforms (knowledge, technology transfer and product production), then we thereby acquire the possibility of collective creativity in creating new types of intellectual forces aimed at subjects of global competition.

The nature, objects and actions of the system design, shown in Fig. 1, aimed at global competition in the sixth technological order are shown in more detail in Fig. 3. . Here subject of competition is characterized by a high level of technology convergence in the NBIC and CCEIC designs (The S (socio) + NBIC design is still being discussed.). The first design means the interpenetration of nano(N), bio (B), info(I) and cogno (C) technologies in order to implement the most complex projects in the history of mankind related to the transformation of resources into intellectual forces in different types of production activities. The second design means transforming resources into intellectual forces for the convergence of cloud computing (CC-cloud computing), enhanced by knowledge about the economic activity of the enterprise (E), modeling of reporting generators (I) and cognitive properties of systems (C).

The second design ensures a transition to the use of intellectual power in those areas where the human brain is still used and where there is a high degree of formalization of information. For example, this concerns the automation of financial reporting and its translation into foreign languages. The conditions under which global competition takes place in the sixth technological order are characterized by the simultaneous presence of technologies from different previous technological orders. At the same time, the main actions of technological chains are aimed at using intellectual forces in various types of human activity

To carry out basic actions, enterprises from technological chains, represented by global industrial centers, acquire the ability to use intelligent shells that help to cooperate the efforts of enterprises in different ways of converting resources into intellectual forces. Cooperation should be based on a logic of action aimed at exchanging experience, using the best standards and dividing labor. In the division of labor, the distribution of components from those countries where the best quality of these products has been achieved is of particular importance. In this case, all actions of distributors aimed at competition must be transparent and impose requirements on product manufacturers to comply with a given level of quality.

The owner of the system design (global industrial center) provides rental of various intelligent shells consisting of platforms of knowledge, technology and production of products. At the same time, the owner determines the subjects of global competition, that is, knowledge, technology and the production of innovative products. With the help of intelligent shells, the owner is able to connect to innovative and financial supermarkets, ensuring transparency, responsibility and high quality in converting the resources of financial supermarkets into the intellectual forces of an innovative supermarket.

In Fig. Figure 4 shows the architecture of the knowledge platform included in the intelligent shell. This platform creates the operating conditions for another platform – the technology platform. The owners of the knowledge platform are primarily universities, scientific institutes, and other industrial centers. Owners carry out actions aimed at objects of accumulation, production and consumption of knowledge to transform resources into intellectual forces. These actions include examination and evidence base of scientific research work (R&D). Competent personnel (scientists and scientific cooperation managers) have the right to use the knowledge platform. These personnel produce products that include fundamental knowledge and publications. Using the knowledge platform, they carry out actions aimed at protecting patents and conduct business examination of the processes of production and consumption of knowledge.

The partner of industrial centers can be the state that is most advanced in the field of innovation, various international regulators for the protection of intellectual property, ensuring an improvement in the technological balance of payments (the balance between income and expenses associated with the development of new technologies). The platform allows for communications with private entrepreneurs who use a global cloud technological resource as an investment in innovation.

The knowledge platform is connected through an intelligent shell and system design to many other intelligent shells, and through them to innovative supermarkets. Such supermarkets play an important role in transforming knowledge into technology, converting financial supermarket resources into intellectual power, and ensuring transparency in the supply of parts for complex products from around the world. Thus, technological chains of enterprises through industrial centers carry out effective forms of cooperation in the international space with the aim of innovative breakthroughs and the development of convergent NBIC and CCEIC products.

Figure 5 shows a technology platform that ensures the transformation of financial supermarket resources into the intellectual R&D forces of a global cloud technology resource. This platform enables enterprise production network platforms to operate in countries as diverse as Japan and the EU, for example. The platform considers technology transfer and convergence as the main subject of competition.

In addition, various mechanisms for regulating rights to technologies are an important subject of competition. Through global technology expertise, we accelerate the transformation of ideas into products.

Platform owners (and this can be both technological chains of small enterprises and individual large enterprises), thanks to project orientation and protective measures, patent protection mechanisms and business expertise, reduce the risks of poor-quality technologies and improve their technological balance of payments. This balance serves as an important indicator of the innovative activity of enterprises, since it reflects income and expenses when performing R&D.

This platform solves the extremely important task of implementing a transparent and high-quality distribution system. In the context of the international division of labor, distribution occupies an important place, since the technological chains of enterprises produce individual parts, and the serial assembly of high-tech products is carried out at one of the large enterprises. Thus, the technological chain, like manufactories from the first technological order, is able to compete with other manufacturers and produce parts and products in general of the NBIC class.

An important link in the technological chain of enterprises is personnel training. Here the main requirements for competencies lie in the area of innovation. Therefore, the main body of specialists consists of scientific entrepreneurs like Edison, as well as qualified engineers. Training and certification of personnel for compliance with competency requirements is carried out within the framework of project seminars accredited among users of the technology platform. And of course, an important circumstance is that this platform provides users with the opportunity to reduce innovative and financial risks when transforming resources into intellectual forces of convergence of NBIC technologies with the help of innovative and financial supermarkets.

In Fig. Figure 6 shows the architecture of the platform for production networks of enterprises connected to each other using cloud communications. Enterprise production networks operate on the basis of this platform. They sell their products through science-intensive supermarkets. Investors and platform owners interact through financial supermarkets, which significantly reduce investor risks. The main subjects of global competition of the platform are knowledge and technologies of consumer lending, to which intellectual forces are directed, including the best standards, exchange of global experience, infrastructure for the division of labor between various enterprises from technological chains, competent technological forecasting, a competent engineering corps and cloud industrial centers.

The main actions of the platform are aimed at improving the technological balance of payments and accessing the resources of innovative supermarkets that ensure transparent distribution of high-tech products. Numerous enterprises from technological chains use cloud communications among themselves to exchange projects based on the use of digital analogues based on a class of solutions instead of physical expensive layouts Product Lifecycle Management (PLM).

Conclusion

Thus, we have very briefly examined the four technological revolutions that have already taken place, which entailed the replacement of objects of competition (knowledge, technology and the production of machines and mechanisms). The actions of motive power (water, steam, electricity and hydrocarbons) were directed to these objects. Then, starting from the fifth technological structure, a revolution occurred, which marked the transition to a qualitatively new design, directing the actions of its intellectual forces to new objects of competition, namely to different types of convergence of nano, bio, info and cogno technologies. At the same time, actions aimed at a new subject of competition began to use a new logic of cooperation (division of labor, use of the best standards and exchange of experience), which provided access to the intellectual powers of the global cloud technological resource.

Literature:

Perez.K. Technological revolutions and financial capital. Dynamics of bubbles and periods of prosperity. M. Case. 2012. 232 p.

Ovchinnikov V.V. Global competition. M. INES 2007. 358 p.

Ovchinnikov V.V. Global competition in the era of a mixed economy. M. INES-MAIB 2011. 152 p.

Ovchinnikov V.V. Technologies of global competition. M. INES-MAIB.2012. 280 pp.

Human nature strives to study the world and transform it. The ability to consciously create something new has determined the role of man in the history of the Earth. The consequences of the love of learning and creating innovations are technologies that make life easier for many people.

Definition and characteristics

Let us define the technological revolution: this is a general term that combines a sharp leap in the development of production methods and an increase in the role of science in the life of the state. This phenomenon is characterized by qualitatively new technologies that increase the level of production, as well as qualitative changes in all spheres of society and human activity. With each new technological revolution, people with the specific skills required for a new production method become increasingly in demand.

Foreign concepts of human development

The issue of the pace of development of scientific progress in the history of mankind has been considered more than once. This problem has been studied from different angles, and several theories are the most popular.

The author of the first foreign concept of technological revolutions is Alvin Toffler, a philosopher, futurist and sociologist originally from the USA. He created the concept of post-industrial society. According to Toffler, there were three industrial and technological revolutions:

- The Neolithic, or agricultural revolution, which began in several regions of the planet at once, represented the transition of mankind from gathering and hunting to farming and cattle breeding. Distributed unevenly across the planet. The Far East began to develop earlier than others along the path of the Neolithic revolution, during the tenth millennium BC.

- The Industrial Revolution, which originated in England in the 16th century. It was accompanied by a transition from manual labor to machine and factory production. Accompanied by urbanization and the introduction of new technologies. It was during the Industrial Revolution that the steam engine and weaving machine were created, and various innovations were introduced in the field of metallurgy. Science, culture and education play a more important role in society.

- Information or post-industrial revolution, which began in the second half of the twentieth century. Due to the development of technology and its increased participation in all spheres of society. A distinctive feature is the multiple increase in various sources of information. The process of robotization of industry begins, the role of human physical labor is falling, and the demand for highly specialized professions, on the contrary, is growing. Entering the post-industrial era implies changes in all spheres of society.

The second concept of human development was put forward by Daniel Bell, an American sociologist. Unlike his colleague, Toffler, Bell divided the stages of human development according to the principle of the invention of a specific object or a certain level of scientific development. Bell identified three types of scientific and technological revolutions:

- Invention of the steam engine in the 18th century.

- Advances in science in the 19th century.

- The invention of the computer and the Internet in the 20th century.

Domestic concept of human development

The following concept of human progress was developed by Anatoly Ilyich Rakitov, a Soviet and Russian philosopher. She divided the history of mankind into five stages, depending on the level of ability to disseminate information. Information technology revolutions:

- Creation of languages of communication.

- The introduction of writing into human society in the VI-IV millennium BC. They appeared in several regions at once: China, Greece and Central America.

- Creation of the first printing press. It was designed in the 15th century and allowed the development of printing, which served as an impetus for progress.

- The invention of the telegraph, telephone, radio at the end of the 19th and beginning of the 20th centuries. This made it possible to transmit information over a distance in the shortest possible time.

- The invention of the computer and the Internet in the second half of the 20th century. This ensured unprecedented growth in the information sphere, opened access to knowledge almost anywhere in the world, provoked an increase in human information needs and ensured their satisfaction.

Features of post-industrial society

Scientific and technological progress contributes to the accelerated development of all spheres of humanity. The main feature of the third technological revolution, during which society enters the post-industrial era, is the constancy of technological development, expressed in the almost complete absence of reactionary forces in the field of scientific knowledge. Thanks to this factor, nothing hinders progress. Another characteristic of the third technological revolution is active investment in the creation of environmentally friendly resources. Development towards environmentally friendly technologies is becoming a priority. The fact of the constant creation of new methods of production and processing of products is also important.

Science and progress

Many changes are taking place in the scientific field. Technological development gives rise to active interaction between many sciences. The tasks that humanity sets for itself in the name of progress can be resolved by using all the scientific potential that it possesses. The consequence of such global goals is the active interaction of sciences, which, it would seem, will always be far from each other. Many interdisciplinary sciences are being created that are actively revealing their potential during the technological revolution. The humanities, such as psychology and economics, are beginning to play an increasingly important role. New disciplines, for example information, are being developed separately. With the beginning of the third technological revolution, more and more highly specialized or even new professions are appearing.

Industrial revolution